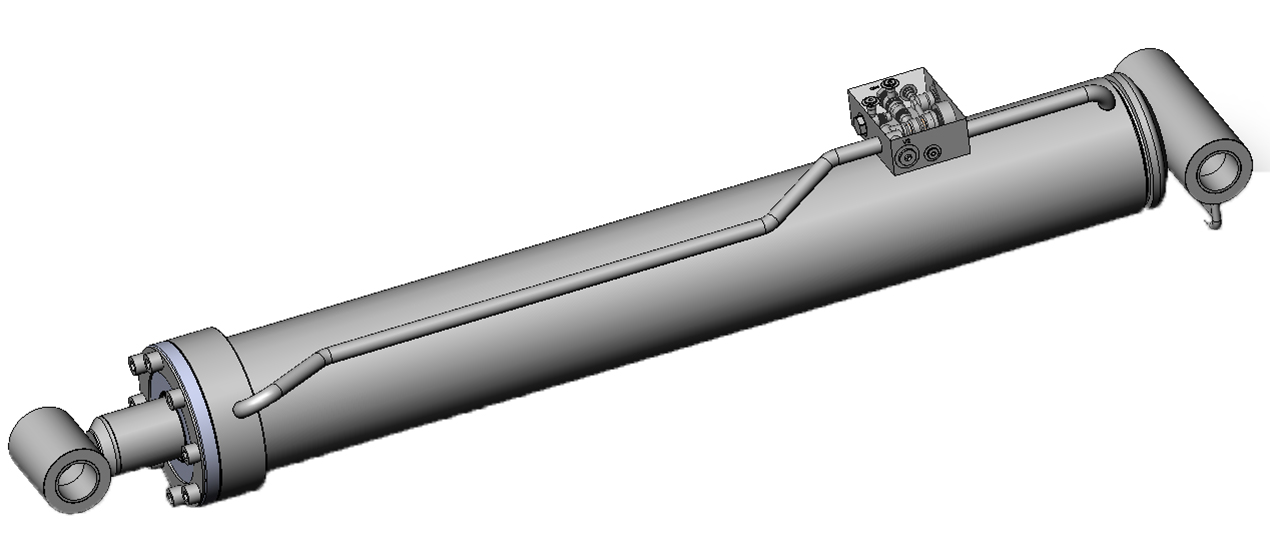

Whatever the equipment: telescopic crane, mini-digger, loader, cherry picker, drilling rig, etc., the expertise of SERTA is recognised by numerous market-leaders for the design and manufacture of hydraulic cylinders, capable of withstanding the mechanical loads imposed by public works.

Technical solutions matched to the needs of the activity sector:

- Bolted hydraulic cylinders to guarantee resistance to pressure peaks,

- Friction welding of attachments to ensure a high-strength connection and excellent resistance to fatigue.

- Shafts treated HF to improve life expectancy and shock resistance,

- Sealing and guide system that is very robust allowing pressure peaks and operating conditions in dusty, sandy, etc. environments and very high radial loads.

- Sealing system with very low internal leak rates, combined with safety systems such as balance and non-return valves allowing position and load holding.

- Position sensors for machine safety and the automation of repetitive tasks,

- Shock absorbers at the end of travel. Fixed, adjustable or progressive,

- Hollow shafts to feed the cylinder via the shaft,

- Shaft coating suitable for your usage conditions (Oxynit, HF)

ALL OF OUR ACTIVITIES

APPLICATION EXAMPLES