Research & Development

Research and development at the heart of our expertise Imagining today

the hydraulic solutions for tomorrow

At SERTA, research and development is part of our DNA. Every day, we strive to improve the performance and reliability of our hydraulic solutions, while exploring new technologies.

Our team uses advanced calculation and simulation tools to design, test, and validate products that are increasingly adapted to the needs of the field. It is this combination of experience, rigor, and technical curiosity that allows us to imagine the actuators of tomorrow.

Our three pillars

of research and development

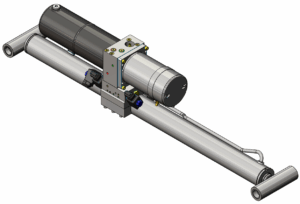

Hydraulic solutions tailored to every need

Innovate

to advance hydraulics

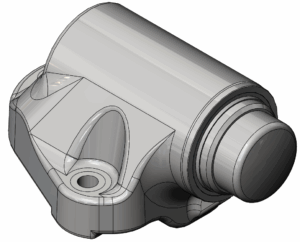

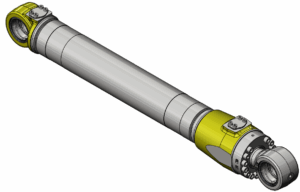

Innovation at SERTA aims to advance hydraulics to meet current and future needs. Our teams are developing new generations of cylinders—high-pressure or molded—combining robustness, compactness, and performance.

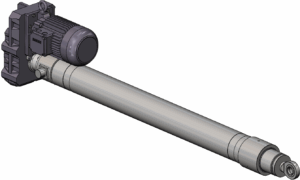

We are also exploring hybrid and electric solutions for more efficient and connected hydraulics.

Thanks to additive manufacturing, we optimize design by adding material only where it is needed, for greater lightness and efficiency.

Each innovation aims to enhance reliability, durability, and energy efficiency, while preserving the flexibility inherent in hydraulics.

Test and qualify

to ensure reliability

Each innovation is tested and validated on our test benches in France, Bulgaria, or China, which are capable of reproducing the most demanding conditions of use.

We test the mechanical strength, hydraulic performance, and durability of our cylinders to guarantee optimal reliability over time.

This rigorous approach allows us to validate our prototypes before series production and ensure that each cylinder meets the highest standards of safety and quality.

Capitalize

to make continuous progress

With more than 30,000 applications developed, we have unique experience in the design and use of hydraulic cylinders.

Each project enriches our technical databases and enhances our simulation and calculation tools, particularly in non-linear finite elements. This capitalization allows us to improve our sizing methods and integrate customer feedback into the heart of our innovation process.

By transforming each experience into know-how, we ensure continuous improvement in the reliability and performance of our cylinders.

Tools and organization designed for efficiency

Our resources and expertise

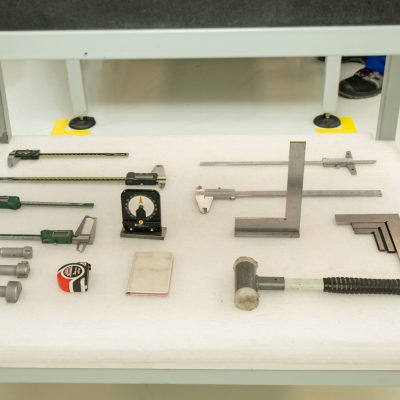

Our research and development team, working closely with production and project managers, uses advanced IT resources and comprehensive test benches to validate the performance of our cylinders under the most demanding conditions.

We also work with partner laboratories to simulate oil flow and perform thermal analysis, further enhancing our understanding of the overall behavior of the cylinder.

Agile research and development close to the field

Our agile R&D department works closely with the project and production teams to quickly adapt its developments, test new approaches, and incorporate feedback from the field.

Thanks to short cycles between idea, simulation, and validation, we can develop reliable, high-performance hydraulic solutions that are adapted to real needs more quickly.

Contact our hydraulic solutions experts

Take action: talk to our experts to design hydraulic cylinders that are perfectly suited to your needs.